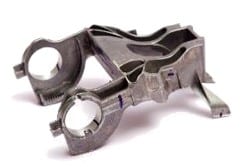

Die Casting

Overview

- Aluminium die casting (LPDC and HPDC)

- Private company, managed by its owner

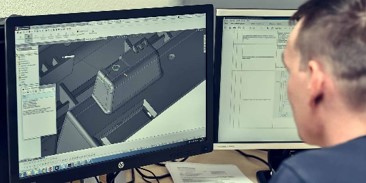

- Own design center with CAD and 3D software (UG and Solid Edge)

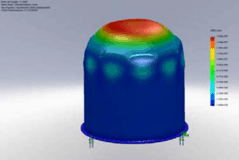

- Own casting simulations

- Own surface treatment and varnishing

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

- In-house pre-machining and finishing of components (4- and 5-axis machines)

- Easy to complex pre-assembly of components

- Component weights between 0.06 kg and 3.5 kg

- Typical alloys:AlSi132 & AlSi9MnMg,AlSi9cu3Fe & ADC10

Quality Management & Capacity

- ISO 9000, TS 16 949, ISO 14001, OHSAS 18001 (2018)

- Quality awards: Bajaj Auto, Kaizen Competition, BAVA Kaizen, Best Support by Varroc, etc.

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

- Capacities over 350 t/month HPDC / 250 t/month LPDC

Company Data

- Year of foundation: 2010 (approx. 50 employees)

- Floor space: 30,000 sqm (thereof 5,200 sqm LPDC and 4,200 sqm LPDC, plus machining and assembly)

- Turnover (2018): 24 Mio€

- Employees (2018): 271

- Tonnage (2018): 6000 (MT)

- Number of shares (2018): > 4.5 million

- Production location: India

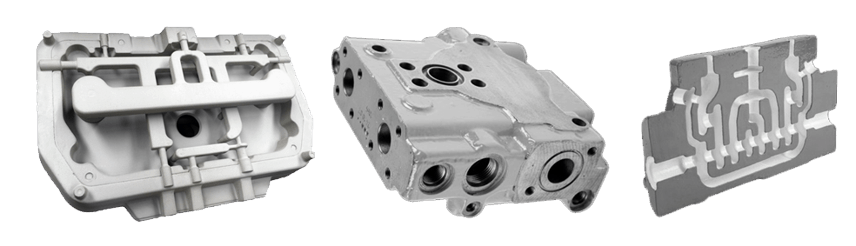

Grey Cast Iron

Overview

- Production of castings from grey and spheroidal graphite iron (GG, GJS)

- Industrial group in the form of a listed stock corporation

- Own design center with CAD and 3D software (UG and Solid Edge); Own casting simulations

- Design and manufacture of high-tech workpieces

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

- Complex machining of cast parts

- Complex pre-assembly of components

- Several Disamatic® systems

- Component weights between 0.1 kg and 30 kg

- Typical alloys:GG, GJS

Quality Management & Capacity

- ISO 9001, TS 16 949, ISO 14001

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

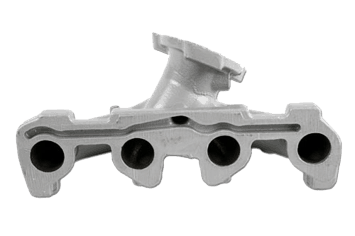

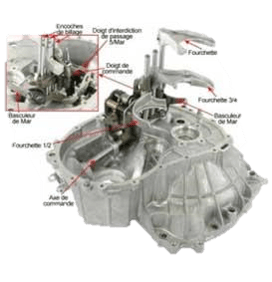

Spheroidal Graphite Iron

Overview

- Production of castings from cast iron with spheroidal graphite (GJS)

- Group subsidiary with strong technological parent company

- Own design center with CAD and 3D software (UG and Solid Edge); Own casting simulations

- Very fast response times

- Design and manufacture of high-tech workpieces

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

- Complex pre-assembly of components

- Very core-intensive components; cold-box cores

- Component weights between 3 kg and 60 kg

- Typical alloys:GJS, Si-Mo, Ni-Resist, Si-Mo-Cr, ADI

- Series production up to 50.000 pcs/year

Quality Management & Capacity

- ISO 9000, TS 16 949, DESP-AD 2000

- Own quality control (3D coordinates, spectrometer, surface inspection, etc.)

- Capacities over 350 t/month HPDC / 250 t/month LPDC

Company Data

- Year founded: 1848

- Floor space: 20,000 sqm (8,000 sqm foundry)

- Turnover: > 25 Mio€

- Employees: 200

- Number of shares (2018): > 1 million

- Production location: France

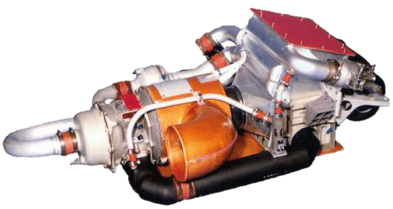

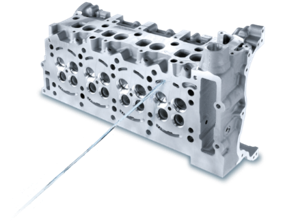

Engines

Overview

- Engineering company and development office

- Aviation systems

- Automotive engineering

- engineering service

- Vehicle testing

- Engine development

- Engine testing (4 test benches with exhaust gas analysis)

- 2 wind tunnels

- Series tuning

- 5-axis machining centres

- Knock wave machining

- Sand casting prototypes

Quality Management & Capacity

- ISO 9001, TS 16 949

- mainframe computer

- Own quality control (3D coordinates, simulations, test benches, etc.)

- CATIA V4/V5, Star-CCM+, Abaqus, Quickcast, GT-Suite

Company Data

- Year of foundation: 1977

- Floor space: 20,000 sqm

- Turnover: > 15 Mio €

- Employees: 150

- Export share: > 40%.

- Place of production: France

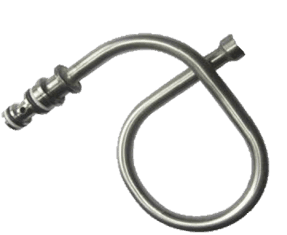

Tubes

Overview

- Production of bent tubes and profiles (10 axes) and their accessories

- Private company, managed by its owner

- Own design center with CAD and 3D software

- Many years of experience in automotive, aviation and special trucks

- Very high precision, Very strong quality assurancePiping for hydraulic systems, fuel supply, air conditioning systems for the automotive and aviation industriesIn-house machining of parts and components (4- and 5-axis machines)

- Complex assembly of components and systemsWelding (TIG, MIG, etc.), Mechanical processing in house

- Component weights from 0.05 kg

- Typical alloys: copper, titanium, aluminium, aisi, superalloy, inconel

Quality Management & Capacity

- ISO 9001:2015, ISO 9100:2016

- Quality prizes: Airbus, Saab, Leonardo, Maserati, Ferrari, Renault, etc.

- Own quality control (3D coordinates, surface inspection, etc.)

- Optical 3D measurement and sampling (CTR 3Dmarking)

- Pressure tightness test: nitrogen up to 150 bar water up to 100 bar oil up to 1,200 bar helium leak test (sniffer)

Company Data

- Relocation into the new hall: 2015

- Floor space: 7,400 sqm

- Sales (2018): > 3 Mio €

- Employees (2018): approx. 20

- Location: Turin (Italy)

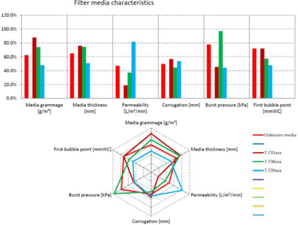

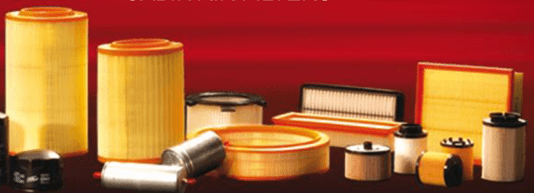

Filters

Overview

- Manufacture of air filters, oil filters, fuel filters and cabin air filters for automobiles and commercial vehicles

- Private company, managed by its owner

- Own design center with CAD and 3D software (SolidWorks, AutoCAD, AUTON, Rhinoceros)

- 3 production sites with special machines

- 21 warehouses in Europe

- Own online catalogue incl. apps (iOS and Android)

- Own development team

- Customers "branding" as desired

- OEM and spare parts market

- Own prototype construction

- Ultrasonic welding

Quality Management & Capacity

- ISO 9001, TS 16 949, ISO 14001

- Quality prizes: Fiat, Renault, etc.

- Own quality control (3D coordinates, surface inspection, flow measurement, etc)

- Optical 3D measurement and sampling (CTR 3Dmarking)

- Own test benches

Company Data

- Year of foundation: 1951

- Base area: 26,000 sqm (of which 15,000 sqm built-up)

- Production (2014): 11 million units/year 50,000 / shift

- Sales (2014): >24 Mio€

- Export share (2014): 44 %

- Location: Italy (EU)

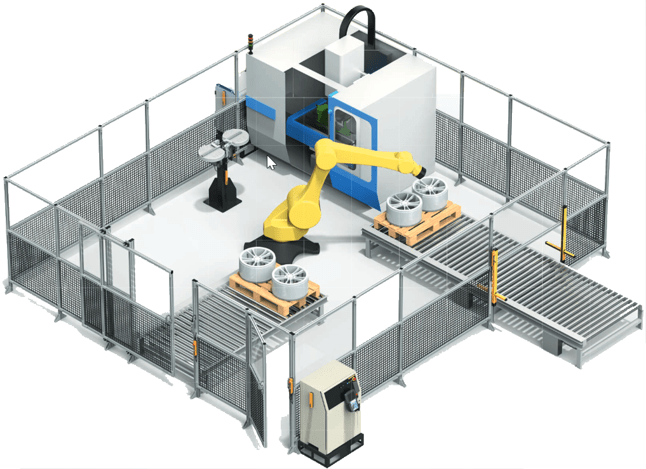

Automation Technology

Overview

- Specialist for robotics, servo technology and precision mechanics

- Automation of production processes

- Own design center with CAD and 3D software (SolidWorks, AutoCAD), 12 workstations

- Design and manufacture of high-tech systems

- Production and assembly technology

- Servo technology and mechanics

- Turnkey plants

- Automotive industry, pharmaceuticals, food, consumer goods, etc.

- Integration of Fanuc, ABB, Kuka, Stäubli, etc. (incl. simulation)

- Video analyses, feeding technology, transfer systems

- Own project management

- Modular technology

- Service and maintenance

Quality & Capacity

- ISO 9001, TS 16 949, ISO 13485, HKZ

- Own quality control (3D coordinates, simulations, etc.)

- Own project management

Company Data

- Year of foundation: 1995

- Floor space: 10,000 sqm

- Turnover: > 3.5 Mio€

- Employees: 30

- export share: > 30%

- Place of production: The Netherlands

Robotics

Overview

- Robot Integration

- Engineering company and development office

- Online programming and commissioning

- Own development center

- Own integration platform

- Automotive industry, pharmaceuticals, food, consumer goods, etc.

- Implementation of flexible robotic solutions

- Integration of ABB, Kuka, Stäubli, etc. (incl. 3D simulation)

- Cycle time / process optimization (offline / online)

- Planning support for complete plants

- interface programming

- Video and SPS connection

- Training and Support

Quality & Capacity

- ProdSG, EN 13849-2 and -2, EN 13850, EN ISO 10218-2, EN ISO 14119 and 14120

- Programming languages C++, Java

- Integration of ABB, Kuka, Stäubli, Fanuc, UR, etc.

Company Data

- Year of foundation: 2004

- Floor space: 200 sqm

- Turnover: > 2 Mio€

- Employees: 25

- Locations: Luxembourg, Germany

Electronics

Overview

- Development of customized electronics

- Engineering company and development office

- Own development center

- Small-lot production

- Service

- Analog Electronics

- Digital Electronics

- Power electronics

- FPGA Development

- Embedded Software

- LabVIEW Software

- Test systems

- Training and Support

Quality & Capacity

- ISO 9001:2015

- ON ISO 13485:2016

- Audits according to ISO 2859

- IEC 61508

- Programming languages C++, Java, Java

- AQL 0.25

Company Data

- Year of foundation: 1982

- Floor space: 500 sqm

- Turnover: > 6 Mio€

- Employees: 80

- Locations: The Netherlands

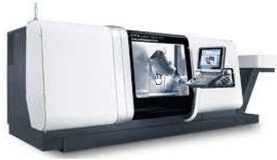

Mechanical Processing

Overview

- Mechanical processing of complex components

- Special know-how in the pharmaceutical and food industry

- Production of complete modules for very different industries

- Own development center

- Machines and plants for oil and gas, hydrogen and food industry

- Own quality assurance (3D measuring machine, roughness test, measuring microscope, spring bench, etc.)

- Clean room ISO class 7

- Complete list of machines on request (Spinner U5, Matec 30 HV, Mazak FJV 250, MAS MCV 1000, STIL 510, Boxan Puma, Charmilles Robofil, etc)

Quality Management & Capacity

- ISO 9001:2015

- VCA 2008/5.1

- Own quality control

- Own initial sampling

- Integration of ABB, Kuka, Stäubli, Fanuc, UR, etc.

Company Data

- Year of foundation: 1994

- Floor space: >1200 sqm

- Turnover: > 6 Mio €

- Employees: 70

- Locations: The Netherlands

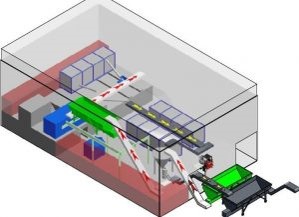

Deburring Technology

Overview

- Manufacturer of systems for deburring technology

- Manufacturer of high-pressure cleaning systems

- Manufacturer of drying plants

- Private company, managed by its owner

- Own design center with CAD and 3D software (UG and Solid Edge)

- Very high specific know-how

- Own mechanical engineering

- Wage deburring

Quality Management & Capacity

- ISO 9001, TS 16 949, ISO 14001

- Own quality control (3D coordinates, spectrometer, surface inspection, etc)

Company Data

- Year of foundation: 1995

- Floor space: 12,000 sqm

- Sales (2018): > 6 Mio €

- Employees (2018): 35

- Production location: France, Germany